Following the success of last year’s inaugural bursaries, The Royal Mint and Heritage Crafts have revealed the recipients four more bursaries to preserve and champion traditional craft skills related to precious metals.

Following the success of last year’s inaugural bursaries, The Royal Mint and Heritage Crafts have revealed the recipients four more bursaries to preserve and champion traditional craft skills related to precious metals.

Heritage Crafts and The Royal Mint received dozens of applications from aspiring precious metal craftspeople, keen to learn from some of the greatest makers across the United Kingdom. Following shortlisting and interviews, four successful recipients were selected, all of whom show huge potential but require additional financial support in order to progress their careers.

The four successful applicants of the bursary scheme will each benefit from up to £4,000 in funding, as well as one-to-one support from Heritage Crafts and The Royal Mint.

The four successful applicants of the bursary scheme will each benefit from up to £4,000 in funding, as well as one-to-one support from Heritage Crafts and The Royal Mint.

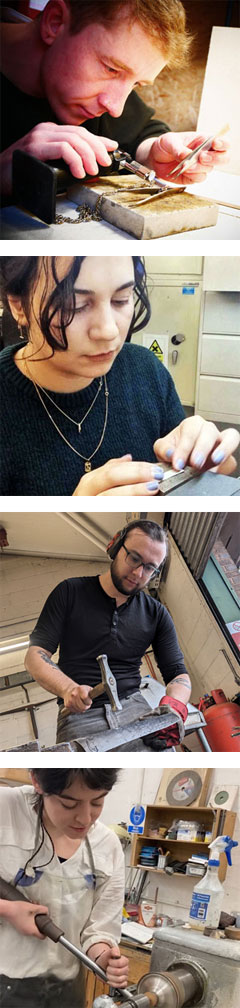

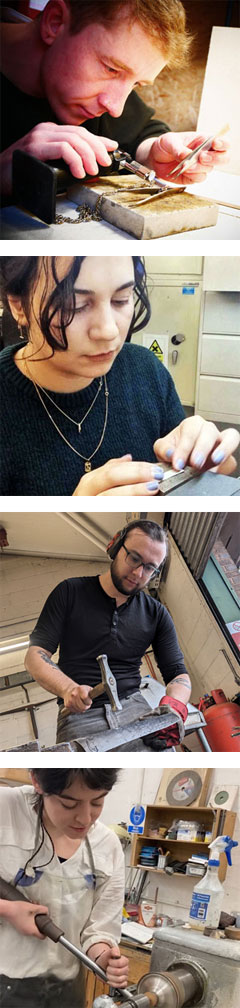

- Richard Barber from Preston will train with renowned jewellery maker Robin Girling in all aspects of stone setting in silver, gold and platinum, with a particular emphasis on ‘fantasy pave’ and ‘micro pave’ setting. Richard has recently set up his own business selling jewellery largely by word of mouth. The techniques he learns on this bursary will enable him to professionalise his offer so jewellery making can become his full-time occupation.

- Andreia Gomes from London will train at the VS Jewellery School in Hatton Garden. She plans to work primarily with gold, but also platinum and palladium, focusing on stone setting and mounting, and casting using the lost wax method. Andreia’s enhanced skills will allow her to secure better opportunities within the jewellery trade, before eventually setting up her own studio.

- Horatio Hawes from Nottinghamshire will extend his internship at Lancaster Armouries, with one-to-one training from master armourer Matthew Finchen, alongside a number of other short courses. His plans are to further explore the use of precious metals within armour making, combining blacksmithing, silversmithing, and goldsmithing techniques in wearable works of art.

- Lily Smith from Dundee will train with Sheffield-based Warren Martin in the craft of silver spinning – the process of shaping a flat silver disk into a hollow item on a lathe, over a former known as a ‘spinning chuck’. It is a critically endangered craft on Heritage Crafts’ Red List of Endangered Crafts with fewer than 15 practitioners in the UK. Lily will use her new skills to spin for the trade, and would like to pass the craft on to others in the future.

The new bursaries follow five previous bursaries awarded in 2023, to silversmiths Iona Hall and Emma-Jane Rule, silver spinners Claire Mooney and Caius Bearder, and jewellery maker Rosie Elwood.

The Royal Mint’s mission is not only to create beautifully crafted, iconic products but also to lead the way in sustainable practices, ensuring that precious metals retain their value and significance for future generations. It crafts investment bullion, coins and heirloom jewellery using pioneering new techniques to protect their future potential, such as reclaiming metals like the gold found in electronic waste and the silver from hospital x-rays. Recovered precious metal is being used to create beautiful jewellery pieces in its latest business venture, 886 by The Royal Mint.

Anne Jessopp, CEO of The Royal Mint, said:

“The Royal Mint is an exemplar of British craftsmanship and we are proud to embrace our duty of promoting, protecting and celebrating British craftsmanship for generations to come. I am thrilled to support this second cohort of precious metal bursary recipients in partnership with Heritage Crafts, and to following the success of all our bursary recipients.”

Daniel Carpenter, Executive Director of Heritage Crafts, said:

“Our partnership with The Royal Mint speaks to the very core of our mission in safeguarding and celebrating traditional craft skills as being of vital importance to the cultural, social and economic life of the UK. We are thrilled to have helped set Richard, Andreia, Horatio and Lily on the path to success in their burgeoning precious metal careers.”

Jay Blades MBE, Co-Chair of Heritage Crafts, said:

“We are delighted to award the second year of bursaries in partnership with The Royal Mint. Their passion for the preservation of British craftsmanship aligns so well with our mission to safeguard these skills for the next generation. Based on the success of last year, we know that these bursaries will provide unique opportunities to precious metals craftspeople that would not previously have been possible.”

This is a part of an ongoing partnership between Heritage Crafts and The Royal Mint that also saw the presentation of the first ever Precious Metalworker of the Year Award in November 2023, to watch dial enameller Sally Morrison from Glasgow, during a special reception at the College of St George, Windsor Castle, and featuring a trophy specially made by The Royal Mint team. In addition, the two organisations hosted a symposium of precious metal practitioners from across the UK at Somerset House in July 2023 to identify the issues facing the sector and what might be done to relieve them.

Heritage Crafts and the Costume Society are delighted to announce the three successful training bursary receipients awarded as part of their new partnership.

Many people are dissuaded from training in the hand skills of fashion textiles because of the cost, and therefore the make-up of the sector is not truly representative of the UK as a whole. This bursary has been set up to help cover or subsidise the training of someone who would otherwise be prevented from pursuing this career path as a result of the cost.

- Mia Brennan – from Kent has attended a number of short millinery courses over the years and gained valuable hands-on experience working freelance one day per week with Vivienne Lake. Her bursary will allow her to attend the BTEC Higher National Certificate in Millinery at Morley College on a part-time basis while continuing her career and earning enough to raise her young daughter.

- Katie Sawyer – from Cheshire is a disabled freelance historic textile craftsperson who began learning heritage crafts with nalbinding and stinging nettle textiles,

before expanding her skills to a wide variety of textile techniques including historical costume, embroidery, needle felting, spinning, knitting and mending. Her bursary will cover one-to-one training with historical textile expert Sally Pointer, as well as various courses at the Manchester School of Costume. Her long-term goal is to become a historical textile leader of the North West, teaching others historic textile skills through workshops and demonstrations.

before expanding her skills to a wide variety of textile techniques including historical costume, embroidery, needle felting, spinning, knitting and mending. Her bursary will cover one-to-one training with historical textile expert Sally Pointer, as well as various courses at the Manchester School of Costume. Her long-term goal is to become a historical textile leader of the North West, teaching others historic textile skills through workshops and demonstrations.

- Maya Howes – from Staffordshire has been creating and selling her work since she was 16, and taking commissions since she was 18. She currently has a small business making historical clothing for re-enactors and theatre, as well as doing local alteration work. Her bursary will allow her to attend the Corsetry Retreat in Lincolnshire to learn 18th century stay making, as well to gain additional one-to-one tuition. Her plan is to focus her business on historical corsetry and stay making, creating comfortable historically accurate garments for museums, re-enactors, and theatre, as well as helping other Autistic and neurodivergent makers into the industry.

The Costume Society is a UK membership organisation formed in 1964 to promote the study and preservation of historic and contemporary dress. As well as training bursaries, its partnership with Heritage Crafts includes a brand-new Fashion Textile Maker of the Year Award launching this summer and an Endangered Fashion Textiles Skills Symposium to take place at the end of the year.

The Costume Society is a UK membership organisation formed in 1964 to promote the study and preservation of historic and contemporary dress. As well as training bursaries, its partnership with Heritage Crafts includes a brand-new Fashion Textile Maker of the Year Award launching this summer and an Endangered Fashion Textiles Skills Symposium to take place at the end of the year.

The bursaries funded by the Costume Society and are three of over thirty to be awarded by Heritage Crafts this year. The next round of applications opens on 29 April 2024.

The Society of Antiquaries of London, in partnership with Heritage Crafts, is thrilled to introduce Illuminator Sarah Davis as the Maker in Residence for 2024 at Kelmscott Manor. This historic residence, once the cherished home of acclaimed writer, designer-craftsman, conservationist, and revolutionary socialist William Morris, will be the backdrop for Sarah’s residency from April to October 2024.

This year (2024) sees the second of three residencies at Kelmscott Manor by members of Heritage Crafts, with a particular focus on an ‘endangered’ craft featured in the 2023 edition of the Red List of Endangered Crafts. During her residency Sarah will be focusing on the endangered craft of Illumination.

This year (2024) sees the second of three residencies at Kelmscott Manor by members of Heritage Crafts, with a particular focus on an ‘endangered’ craft featured in the 2023 edition of the Red List of Endangered Crafts. During her residency Sarah will be focusing on the endangered craft of Illumination.

The project presents an opportunity to showcase endangered crafts in an iconic rural setting visited annually by over 27,000 people.

Memoria Lewis, General Secretary of the Society of Antiquaries, said:

“After a successful first year of our Maker in Residence programme I’m delighted to see our partnership with Heritage Crafts continue. I’m excited that we are championing an endangered craft this year and bringing awareness of these to a wider audience. Sarah’s expertise as an illuminator will no doubt inspire those interested in the craft and those who have never seen the beauty of an illuminated text. I can’t wait to see Sarah’s response to Kelmscott and the work she develops during her time with us.”

Sarah’s appointment as the 2024 Maker in Residence at Kelmscott brings with it the unique opportunity to reflect Morris’s advocacy of heritage and the handmade and contribute to his legacy by playing a distinctive part in the Manor’s programme of public engagement. Visitors will be able to discover the endangered art of illumination through hands-on workshops and demonstrations led by Sarah throughout her residency. Sarah will also share her historic craft with education groups as part of our Learning & Outreach programme.

Sarah Davis, 2024 Maker in Residence, said:

“As this year’s Maker in Residence at Kelmscott Manor, I am thrilled to highlight the endangered craft of illumination. Guided by the manor and its beautiful surroundings, I see this as an opportunity to grow as an illuminator and to deepen my knowledge of this stunning endangered craft. Inspired by the enduring legacy of William Morris, his commitment to craft skills and fellowship, I look forward to sharing what I learn with visitors to the manor and the wider community online.”

Daniel Carpenter, Heritage Crafts Executive Director, said:

“Morris believed in the enduring relevance of crafts that had been passed down through the generations, as well as the necessity of their continual evolution in order to secure their place within an ever-changing society. We are delighted to be working with the Society of Antiquaries for a second year, focusing on crafts the continuation of which modern society has put obstacles in the way, but that we believe can have a viable future. Sarah’s craft is a wonderful example of this and she is perfectly placed to continue Morris’ legacy of maintaining the contemporary relevance of mediaeval craftsmanship.”

Sarah’s appointment as the Maker in Residence is made possible as part of our NHLF- funded £6 million Kelmscott and Morris: Past, Present and Future project.

Maker bio

Sarah Davis is a multi-media artist exploring themes relating to the cyclical nature of recovery and renewal. The natural world serves as a deep pool of inspiration with the allegory, myth and folklore of animalistic subjects driving her narrative approach. Davis uses traditional making techniques with a deep historical resonance, such as wood carving, gilding and illumination. Since 2020 Sarah has been practicing the art of illumination which is listed on the Heritage Crafts Red List of Endangered Crafts.

In 2012 Davis graduated from Chelsea college of art with a BA in Fine art. She returned to education in 2015 to study woodcarving and gilding at the City & Guilds of London Art School, where she now teaches on the Woodcarving BA & Conservation BA.

Meet the Kelmscott Manor Maker in Residence at London Craft Week

When: 13 May 2024, 10.45am to 12pm

Where: Burlington House, Piccadilly, London W1J 0BD

Cost: £15 to include refreshments

Join a panel discussion with 2023 Maker in Residence ceramicist Alison Proctor and newly-appointed 2024 Maker in Residence ceramicist Sarah Davis, alongside Kelmscott Manor’s Kathy Haslam and Hannah Britton, and Heritage Crafts’ Daniel Carpenter. Hear about how Alison’s residency progressed in response to the site and Morris’ legacy, see her work first-hand, and listen to Sarah’s hopes for the coming year.

Book here: londoncraftweek.com/events/meet-the-kelmscott-manor-maker-in-residence

Recorded: 13 March 2024

Topic: Stained glass artist

Go back to In Conversation menu

Deadline: 24 May 2024, 5pm

The first round of the Heritage Crafts Awards in 2024 are now open for nominations, with 12 prizes over seven award categories up for grabs. The Awards, which have been running since 2012, celebrate and highlight the traditional living crafts that contribute to British heritage.

The first round of the Heritage Crafts Awards in 2024 are now open for nominations, with 12 prizes over seven award categories up for grabs. The Awards, which have been running since 2012, celebrate and highlight the traditional living crafts that contribute to British heritage.

The President’s Award for Endangered Crafts, now in its fifth year, was established by Heritage Crafts President The Former Prince of Wales. Each year the President’s Award presents £3,000 to a heritage craftsperson who will use the funding to ensure that craft skills are passed on to the future.

The second annual Environmental Sustainability Award, in partnership with the Queen Elizabeth Scholarship Trust (QEST), will this year award two £1,000 prizes, open to craftspeople working with traditional craft skills or materials who have demonstrated an innovative approach to environmental sustainability or transformed the environmental impact of their craft business through a series of incremental changes and improvements.

The tenth annual Maker of the Year Award will this year award four £1,000 prizes, to heritage craftspeople in England, Northern Ireland, Scotland and Wales, who have made an outstanding contribution to their specific crafts within the previous 12 months, with support from the Maxwell/Hanrahan Foundation. An overall UK Maker of the Year will be selected from the four national winners, with their prize topped up to £2,000, with support from the Marsh Charitable Trust.

The tenth annual Maker of the Year Award will this year award four £1,000 prizes, to heritage craftspeople in England, Northern Ireland, Scotland and Wales, who have made an outstanding contribution to their specific crafts within the previous 12 months, with support from the Maxwell/Hanrahan Foundation. An overall UK Maker of the Year will be selected from the four national winners, with their prize topped up to £2,000, with support from the Marsh Charitable Trust.

The Marsh Charitable Trust will support four other awards, including Trainer of the Year, Trainee of the Year, the Lifetime Achievement Award, and the new Community Catalyst of the Year Award.

List of awards open until 24 May 2024:

Anyone, including the makers themselves, can nominate for this award. The deadline for applications is 5pm on Friday 24 May 2024 and you can find out more about each award, as well as how to apply, at awards.heritagecrafts.org.uk. The award winners will be announced at a high-profile Winners’ Reception in November 2024.

A second round of awards will open for nominations on 17 June, including Woodworker of the Year, Precious Metalworker of the Year, Fashion and Textile Maker of the Year, Leatherworker of the Year and others, as well as range of awards for young makers aged 25 and under.

Following the success of last year’s inaugural bursaries, The Royal Mint and Heritage Crafts have revealed the recipients four more bursaries to preserve and champion traditional craft skills related to precious metals.

Following the success of last year’s inaugural bursaries, The Royal Mint and Heritage Crafts have revealed the recipients four more bursaries to preserve and champion traditional craft skills related to precious metals. The four successful applicants of the bursary scheme will each benefit from up to £4,000 in funding, as well as one-to-one support from Heritage Crafts and The Royal Mint.

The four successful applicants of the bursary scheme will each benefit from up to £4,000 in funding, as well as one-to-one support from Heritage Crafts and The Royal Mint.

before expanding her skills to a wide variety of textile techniques including historical costume, embroidery, needle felting, spinning, knitting and mending. Her bursary will cover one-to-one training with historical textile expert Sally Pointer, as well as various courses at the Manchester School of Costume. Her long-term goal is to become a historical textile leader of the North West, teaching others historic textile skills through workshops and demonstrations.

before expanding her skills to a wide variety of textile techniques including historical costume, embroidery, needle felting, spinning, knitting and mending. Her bursary will cover one-to-one training with historical textile expert Sally Pointer, as well as various courses at the Manchester School of Costume. Her long-term goal is to become a historical textile leader of the North West, teaching others historic textile skills through workshops and demonstrations.

The Costume Society is a UK membership organisation formed in 1964 to promote the study and preservation of historic and contemporary dress. As well as training bursaries, its partnership with Heritage Crafts includes a brand-new Fashion Textile Maker of the Year Award launching this summer and an Endangered Fashion Textiles Skills Symposium to take place at the end of the year.

The Costume Society is a UK membership organisation formed in 1964 to promote the study and preservation of historic and contemporary dress. As well as training bursaries, its partnership with Heritage Crafts includes a brand-new Fashion Textile Maker of the Year Award launching this summer and an Endangered Fashion Textiles Skills Symposium to take place at the end of the year. This year (2024) sees the second of three residencies at Kelmscott Manor by members of Heritage Crafts, with a particular focus on an ‘endangered’ craft featured in the 2023 edition of the

This year (2024) sees the second of three residencies at Kelmscott Manor by members of Heritage Crafts, with a particular focus on an ‘endangered’ craft featured in the 2023 edition of the  The first round of the Heritage Crafts Awards in 2024 are now open for nominations, with 12 prizes over seven award categories up for grabs. The Awards, which have been running since 2012, celebrate and highlight the traditional living crafts that contribute to British heritage.

The first round of the Heritage Crafts Awards in 2024 are now open for nominations, with 12 prizes over seven award categories up for grabs. The Awards, which have been running since 2012, celebrate and highlight the traditional living crafts that contribute to British heritage.  The tenth annual Maker of the Year Award will this year award four £1,000 prizes, to heritage craftspeople in England, Northern Ireland, Scotland and Wales, who have made an outstanding contribution to their specific crafts within the previous 12 months, with support from the Maxwell/Hanrahan Foundation. An overall UK Maker of the Year will be selected from the four national winners, with their prize topped up to £2,000, with support from the Marsh Charitable Trust.

The tenth annual Maker of the Year Award will this year award four £1,000 prizes, to heritage craftspeople in England, Northern Ireland, Scotland and Wales, who have made an outstanding contribution to their specific crafts within the previous 12 months, with support from the Maxwell/Hanrahan Foundation. An overall UK Maker of the Year will be selected from the four national winners, with their prize topped up to £2,000, with support from the Marsh Charitable Trust.